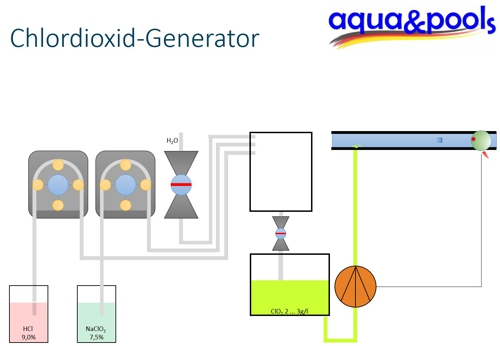

Tutorial chlorine dioxide generator

Chlorine dioxide is used worldwide as a disinfectant and more important. This success is built: by the toxic effects on organisms, the high degree of independence from the pH of the water and the difference of the reaction by-products of chlorine dioxide to the reaction by-products of chlorine. A detailed justification for the use of chlorine dioxide should be read in newspaper articles to Filterverkeimung and in the tutorial to Legionella. The theme of the following lines is the on-site production (in situ) shown of chlorine dioxide in a generator.