no guarantee for the accuracy of the informations

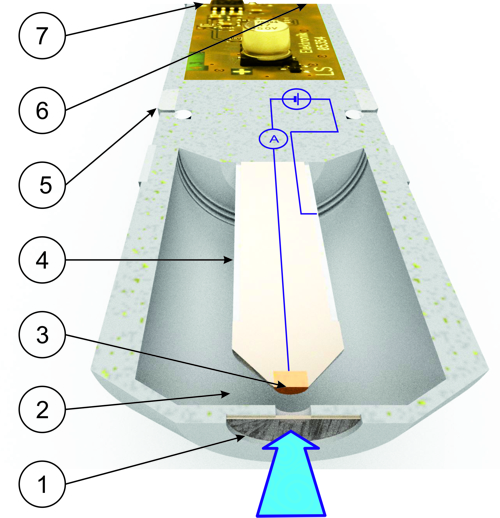

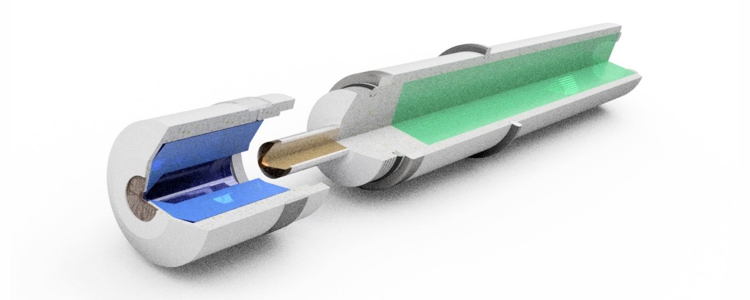

2-Elektode systems

A nozzle of the flow-through chamber with 6mm diameter approximately 15 millimeters distance brings a constant jet of fluid (symbolized by a blue arrow) with the disinfectant in a direction plumb to the membrane (1). The membrane allows molecules of the disinfectant mainly pass through . These molecules put a pathway in the electrolyte liquid (2) to the working electrode (3) back. The working electrode (3) is of precious metals (gold or platinum) so they do not corrode. The working electrode (3) is with a very small but accurate electrical voltage. Therefore, the disinfectant emits electrons at the surface of the working electrode. These electrons flow to the reference electrode (4) and forming a very small electric current. This electric current is measured and is compensated with temperature to an electrical output signal (6) processed. This signal may be a standard voltage signal from 0 to -2000 millivolts or a standard current signal 4 to 20 milliamps or a standard bus signal "ModBus RTU".

The reference electrode (4) has a very thin silver-salt-coating. Together, these coating and the electrolyte form a very precise voltage zero point. Only this exact zero point allows, set the exact electrical voltage for the surface of the working electrode.

In addition to the signal connector (6) is depends on the type of the output signal a voltage supply (7) required.

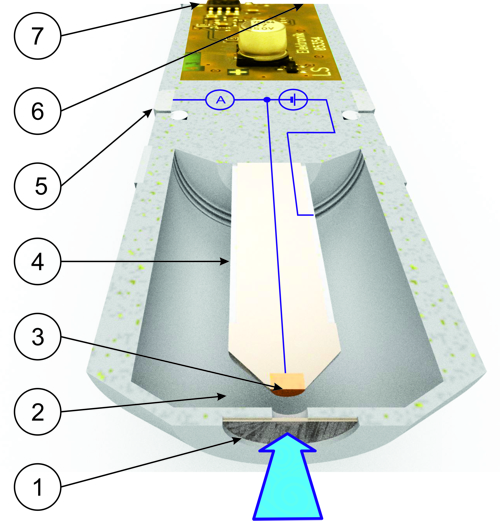

3-Elektode systems

A nozzle of the flow-through chamber with 6mm diameter approximately 15 millimeters distance brings a constant jet of fluid (symbolized by a blue arrow) with the disinfectant in a direction plumb to the membrane (1). The membrane allows molecules of the disinfectant mainly pass through . These molecules put a pathway in the electrolyte liquid (2) to the working electrode (3) back. The working electrode (3) is of precious metals (gold or platinum) so they do not corrode. The working electrode (3) is with a very small but accurate electrical voltage. Therefore, the disinfectant emits electrons at the surface of the working electrode. These electrons flow in the 3-electrode system to the counter-electrode (5) and forming a very small electric current. The counter-electrode (5) be seen as a ring made of stainless steel. By this method, the reference electrode (4) kept current-free. The current is measured and the temperature to an electrical signal (6) processed. This signal may be a standard voltage signal from 0 to -2000 millivolts or a standard current signal 4 to 20 milliamps or a standard bus signal "ModBus RTU".

The reference electrode (4) has a very thin silver-salt-coating. Together, these coating and the electrolyte form a very precise voltage zero point. Only this exact zero point allows, set the exact electrical voltage for the surface of the working electrode.

In addition to the signal connector (6) is depends on the type of the output signal a voltage supply (7) required.

Leave a Reply

You must be logged in to post a comment.