no guarantee for the accuracy of the informations

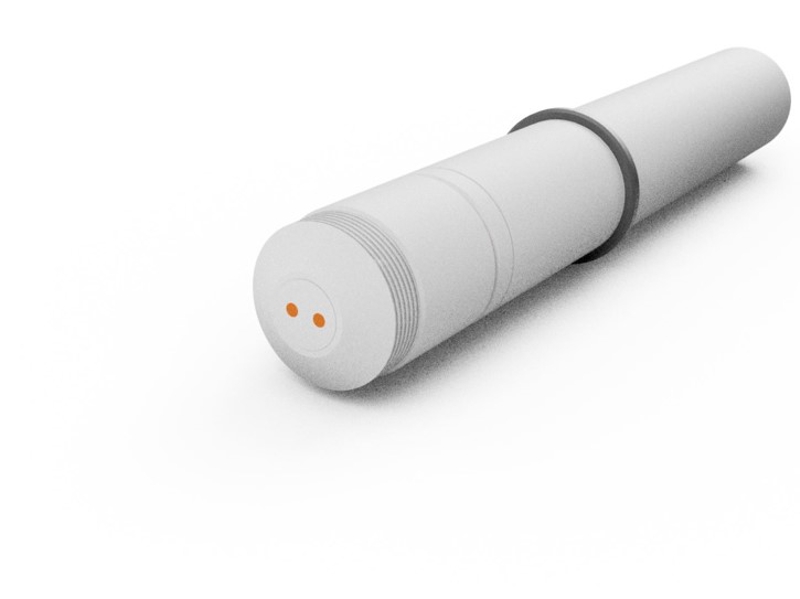

Amperometric sensor without a membrane, the first step for cleaning device

In the membrane-covered amperometric sensor, the working electrode is separated from the water and disinfectant by a most sensitive membrane. A cleaning device is not realizable. This membrane may be by substances, which are located in water, be contaminated. This contamination holds the molecules to be measured back and reduces the sensitivity of the measurement.

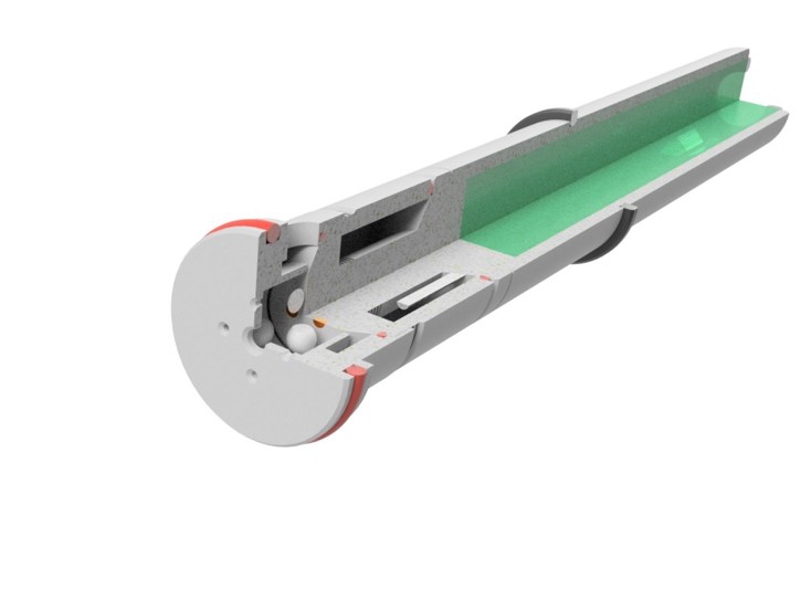

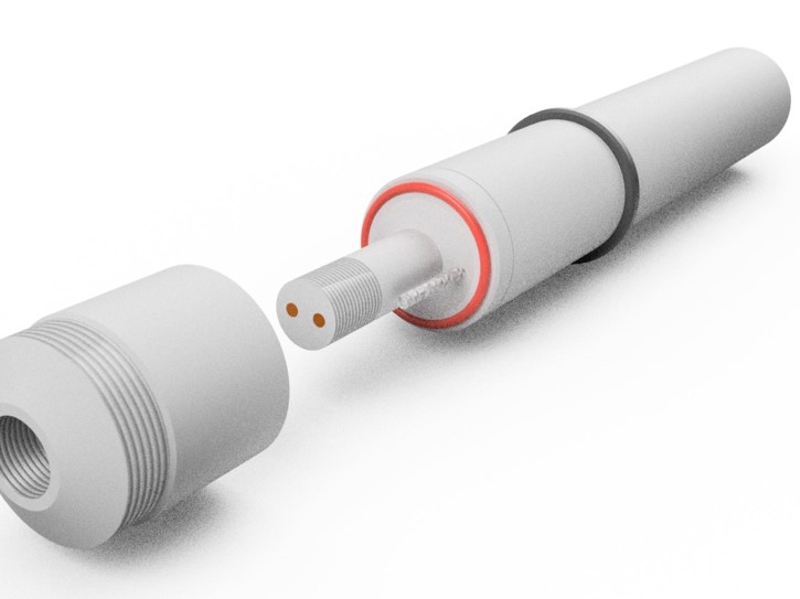

Caused by the membrane, a membrane-covered amperometric sensor is sensitive to pressure. For some disinfectant there is the possibility, carry out the measurement without membrane. The missing membrane leads to a pressure stability of the sensor. At the same time this case, the working electrode is exposed, so that the surface can be cleaned mechanically.

Function as 3-electrode system

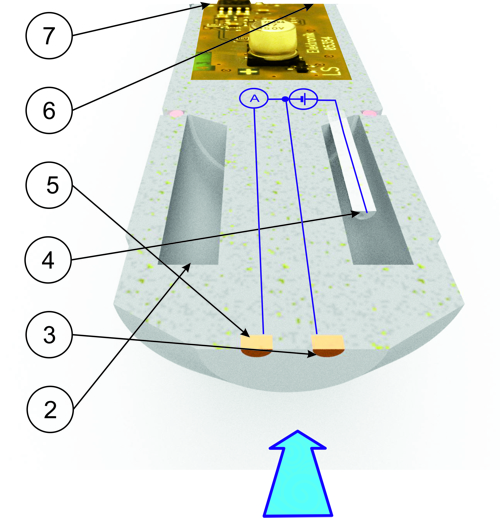

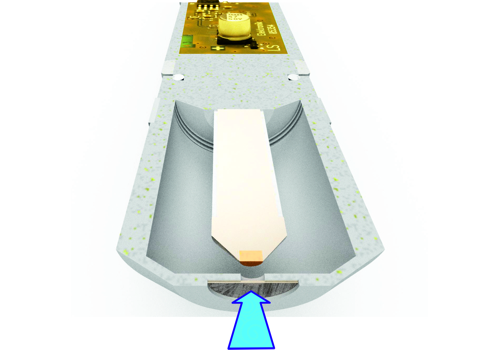

A nozzle of the flow-through chamber with 6mm diameter approximately 15 millimeters distance brings a constant jet of fluid (symbolized by a blue arrow) with the disinfectant in the perpendicular direction of the working electrode (3). A membrane, otherwise with (1) marked, is not present. These molecules directly hit the working electrode (3). The working electrode (3) is of precious metals (gold or platinum) so they do not corrode. The working electrode (3) is with a very small but accurate electrical voltage. Therefore, the disinfectant emits electrons at the surface of the working electrode. These electrons flow in the 3-electrode system to the counter-electrode (5) and forming a very small electric current. The counter-electrode (5) is provided as a second point adjacent the working electrode (4) recognizable. By this method, the reference electrode (4) kept current-free. The current is measured and the temperature to an electrical signal (6) processed. This signal may be a standard voltage signal from 0 to -2000 millivolts or a standard current signal 4 to 20 milliamps or a standard bus signal "ModBus RTU".

The reference electrode (4) has a very thin silver-salt-coating. Together, these coating and the electrolyte form a very precise voltage zero point. Only this exact zero point allows, set the exact electrical voltage for the surface of the working electrode.

In addition to the signal connector (6) is depends on the type of the output signal a voltage supply (7) required.

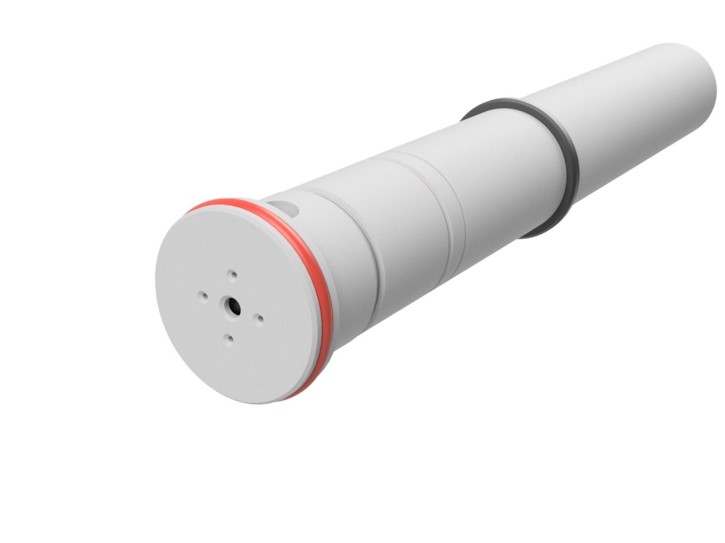

Function of the cleaning device

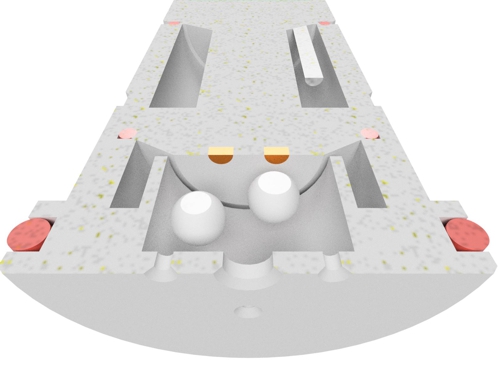

The water jet is due to the outer seal (red sealing ring) passed through the central main opening. 4 small secondary openings create turbulence in the cavity behind. This turbulence is sufficient, to 3 balls move, which located in this space.

Randomly the balls hit the surface of the working- and the counter electrode. The existing friction is sufficient, to keep clean the surfaces.

The cleaning with 3 balls has incidentally result, that the sensitivity of the measurement tripled. This should be considered when selecting the sensor. The Tutorial for selecting a membrane-covered amperometric sensor considers this change the measuring range.

Data sheets of the sensor for registered users:

[wpdm_package id=’1981′] [wpdm_package id=’1983′]

Leave a Reply

You must be logged in to post a comment.