In the employee relationship within the Dosatronic GmbH in the position of Technical Director, the development of a regulator in the slogan "INTERNET OF WATER" I initiated, continued and completed the first target status. Previously, the DOSATRONIC GmbH has a variety of other brands bought and sold as an OEM product. The biggest weakness of these devices was the lack of communication with decentralized systems. As a second weakness, the communication with the operator via the line-oriented display was identified. So, the goal was a modular controller with an embedded Web server, which performs the communication based on HTML. The features of this controller are in detail here described.

Description

The monitoring of water quality is carried out frequently online (is meant in the water volume flow). The measured parameters are often limited to the pH, the Redox value and the concentration of free chlorine. From this historically grown request a variation of devices has been created, which one, two or three parameters can detect and evaluate. These variations are however limited by the frequency of measurement and required by the costs. The modularity of the device should therefore consciously attract customers, who require unusual combinations or who want to change the combination later.

Measurement

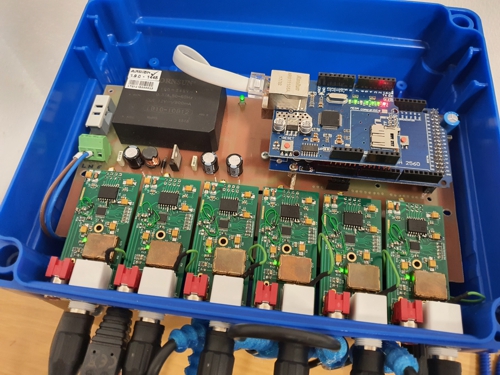

The measurement is distributed to individual modules, which are galvanically separated from each other. Besides the main modules, the device is equipped with necessary auxiliary parameters. These parameters are temperature via Pt100 for compensation and several digital inputs. The measurement may include sensors for pH, Redox-, free chlorine, total chlorine, Ozone, H2O2, Peracetic acid, chlorine dioxide and other sensors use .

Currently the last member of the family of modules is one to measure the conductivity. In this module, additional input for temperature is integrated.

control

A controller is often overwhelmed, if the time between the input signal and the effect on the real process (the so-called jump-response) is very long. Vibrations occur. So that the affected customer does not cause unnecessary support effort, the existing controller modes are explained in detail in the User's Guide. In addition, an adaptive controller mode has been installed, which can operate without the usual parameters of PID.

Source: Dosatronic GmbH

The company is located here:

Display of localization in the external Link.

My services:

- Design of the overall device,

- Concept of the modules,

- Development of sensor algorithms,

- Development of control algorithms,

- Planning and monitoring of development,

My client:

- DOSATRONIC GmbH, Ravensburg,

Sources:

-

-

- https://pixabay.com

-

Leave a Reply

You must be logged in to post a comment.