In the highlands of Ethiopia was build 2015 probably the world's largest brewery company Dashen. In an otherwise very water-deficient environment wells were drilled, which produce several thousand cubic meters of water every day. 132 km or 150 Minutes away by car, outside the city Debre Berhan ("Mountain of Light"), next to the fountain a large area for the brewery was opened. Here traditional African ways of life met with European technology.

Description

The well water is promoted, then passed through closed sand filter made of stainless steel into containers and then repeatedly treated in a circle about this filter. Of course, in order to optimize a flocculant is used and the pH value. The 4 are containers, each with several thousand cubic meters volume as storage and backup for the production of 4 days used. To protect against bacterial infections, the water is disinfected immediately after filtering constant with chlorine dioxide. During storage in the tank, the water is moving and maintaining the concentration of chlorine dioxide at a constant value.

Production of chlorine dioxide

The used for disinfection, chlorine dioxide is produced locally from hydrochloric acid and sodium. The chemicals come from a local supplier and filled into containers. The reaction to chlorine dioxide is brought about by dilution with water into a low-risk area. These investments were 12 been months earlier delivered by the company DOSATRONIC GmbH from Germany. Despite training of employees from the South African engineering firms had failed on site, to take the generators in operation. Here I had to help.

Measurement

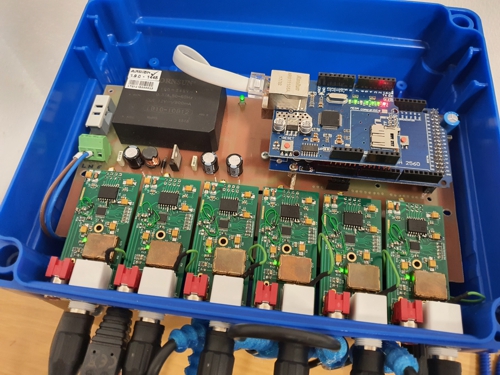

The measurement of the concentration of chlorine dioxide is carried out continuously at several points of the system. The measuring system is a combination of DOSACompact potentiostatic measurement of disinfectants, the redox- and the pH measurement. While compensating the temperature and the volume flow very accurate measurements can thus be achieved. The reference measurement and the calibration is performed by our own laboratory of the brewery. The challenge was, instruct the local personnel in the relationships between the parameters and in the conditions of a measurement.

The readings are on my initiative by 4…20mA signal transferred to the central control and logged there. Transmission over the better ModBus RTU protocol was not planned, unfortunately, in the central controller.

Control

The volume flows of the water outside the container are detected by measuring devices. These instruments provide the associated diaphragm pump 4…20mA-Signal. The dosage, once set, is proportional to the volume flow.

The concentration in the tank is compared with a desired value measured. The controller in DOSACompact operates over a PI controller, and outputs digital pulses with different distances to the associated solenoid diaphragm pump.

The measurement- and dosing since run without interruption and enable the production of the best beer.

The object is located here:

Display of localization in the external Link.

My services:

- Commissioning chlorine dioxide generator,

- Setup measurement- and control system

- Training of employees on site

My client:

- DOSATRONIC GmbH, Ravensburg

- PROSEP Chemicals SA, South Africa

Sources:

-

-

- https://pixabay.com

-

Leave a Reply

You must be logged in to post a comment.