Published in: Das Schwimmbad und sein Personal, edition 10/2016

... or what should and can filter my filter?

Of course now, no member of our Association should feel addressed by the title (have to). Unfortunately, this claim is too common outside of Germany. Not rare to find sand filter without sand, Precoat filters without diatomaceous earth and filter without filter flushing.

This post will not compare between different filter systems. This has often been written with more or less sponsorship support from one point of view or another. At the same time I would like to make no assumptions about new or unknown filter systems - without having the necessary experience in the bag. I prefer to give food for thought, which are transferable to other systems. So it's below solely to the depths filtering through sand filters.

In one we are certainly in agreement: The optimal function of filtering is the basis for good water quality!

Circulatory system

But a big mistake I want to fight right at the start. The sand filters are not considered in many publications from the direction of pools. Swimming pools have, as we all know, the peculiarity, that the water is treated in the circuit. This has a number of disadvantages, but has also some advantages. But for an assessment you should always have it in mind. We will point on the necessary places to the differences.

What should and can filter my filter?

OK, it filters the water of the pool. So we must ask the question differently: What should the filters remove from the water? The filter is still usually the only stage of the process, which substances removed from the water. Thus, the question can easily answer: Everything should be removed, what comes through the use as a swimming pool in the water. Do we want times not to go deeper, what is "intended" and "improper" use. The fact is, that all bathers leave their traces back in the water. The outdoor pool still leaves or birds come with their consequences to, but we are aware of that. But it is not that easy, because the residues are not always right "filterable". Some are liquid and fight back, while others are too small for every pore.

How much must get out?

Now you can not ask any bather before visiting the swimming pool, what will he give to the water. Even the bathing caps of our ancestors in combination with the depilatory urge of the current youth do not protect us from dander, Hyaloron-acid-containing daily- or night-products or exclusive men's care. Following my personal interpretation, because as a written scientific basis of DIN 19643 I have not found in this relationship, one can imagine a simplified mean value for the pollution by the "common German" bather.

Probably in many major statistical studies have identified, that each bather releases a lot divers substances in the water. The composition is not quite so simple, let's say it is on the one hand carbon-based and the other is nitrogen-based compounds. Urea, for example, clearly nitrogen-based.

Now you can not analyze all compounds from the water with an extremely expensive device, therefore, as is often the case in life, you introduce a cheap replacement measurement.

Since the ingredients can not be determined individually, an oxidizing agent is dosed, which likes to give off oxygen. The consumption of this oxidizing agent is measured, and with the contents of (oxidizable) organic substances set equal to. The commonly used agent is potassium permanganate, the consumption of 4 milligrams of KMnO4, so the stuff is written, corresponds to approx. 1 Milligrams of oxygen O2. The consumption of O2 is therefore proportional to the contained (mostly) organic substances, which in turn are equated with contamination.

Surprising, but somehow not surprising, the Oxidisability then also found in the leaflet 65.04 in point 6.2 to verify the procedure efficacy. In my view, these particulars are difficult to understand and make a huge room for interpretation. Pity, that I could not find any concrete values here, so I'll guess so the evaluation of the results.

My personal interpretation: A filter system to a swimming- or bathing pool, both according to DIN 19643 dimensioned and built, is by definition able, to eliminate the residues of bathers with standard usage within two filtration runs.

Of course difficulties make real dissolved compounds, as these can not be filtered! Detergents in the water increase the KMnO4-consumption, but can not be removed by filtration. But where is already expected, that water treatment company and cleaning company each other "shoot in the foot"? If only, the detergents increase the phosphate concentration too. In case of dispute a search help!

Why does not it work without filters?

It actually works! The oxidation, which we have explained here above in such detail, works without filter instead

with chlorine. Many Eastern European pools demonstrate it to us every day. Their recipe: Take good dirty unfiltered water and give added as much granulated chlorine with the shovel. This gives not only red eyes but also heavy breath and after a while also a cancer in the lungs. The end product of the oxidation by means of chlorine is unfortunately bounded chlorine, which is fortunately limited in our DIN 19643 swimming pools.

The filtration is abroad, so you can call the filtration ever so, often only a particular section of the pipes. Even at the first glance is usually recognizable, that cleaning of the filter can not work. Missing or incorrect fittings make the unit absurdity.

Let's get an overview

In the depth filtration through sand as opposed to surface filtration (precoat-, Ultra-) the particles to be separated from the fluid are retained in the interior of a granular filter layer.

During the filtering the water flows through the filter layers from top to bottom. It acts in addition to forces from the fluid flow and the gravitation on the grains of sand. systems, which would like to outwit these forces, have after my suggestion major disadvantages. After the end of the filter runtime, so when the

loss of pressure in the filter comes to its economic limit, the filter must be regenerated by flushing. This is done in the reverse direction. Subtleties to that later. For the sake of completeness: The distances between the filter rinses are dependent not only on the contamination but also on the growth rates possibly in the filter layer domestic bacteria!

So that the filtration works in the depth of the sand filter, the particles to be separated must be significantly smaller, but just big enough, be than the pore size of the grains. The reverse is: The size of the particles filterable has little to do with the size of grains of sand.

The deposition of the particles within the filter layer consists of 2 features, transporting the water to the filter-grain ingredients and the adhesion of the particles on the surface of the grain. The conditions, under which the liability is done, beyond this (unscientific) frame. If necessary, but everyone can at GIMBEL (1984) read up.

What has to happen with the substances, the do not adhere to the filter-grain?

So a sand filter can not drop everything! He relies on the cooperation of the process steps. What the sand filter can not filter off must be made filterable!

So it is described in the process steps of the DIN 19643, almost always it says "... flocculation, Filtration, Disinfection ... "or similar. At first glance, the viruses and the bacteria seem to us interesting. They would pass through the filter almost unhindered, if they were not captured in flakes. But for a clean (harmless) Water, other parameters are important too.

If hiding in the real solutions phosphates, the algae are happy in the water about good nutrition. Who wants that?

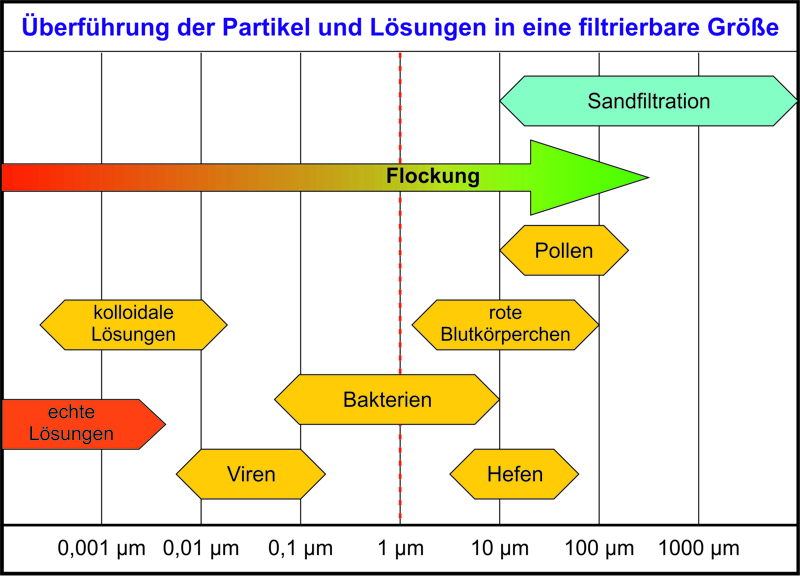

For this purpose the following chart with the sizes of the particles of interest:

Graphic 1: Effect of flocculation on particle sizes, aqua&pools

Some "residues" of bathers hide in the non-filterable particles as well as in colloidal solutions. Just think of the oils and fats, which will be applied to the water before jumping. In the upper diagram, this transformation is shown by the arrow.

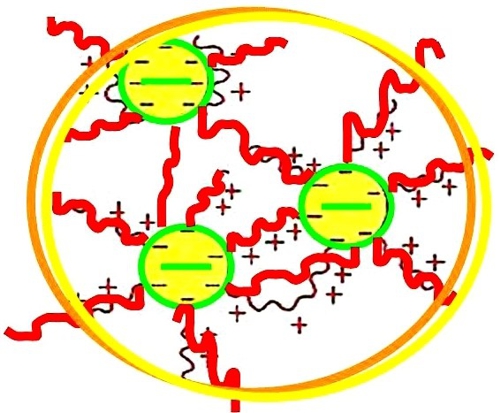

Flocculation works in different ways. Roughly speaking, the polarities of the particles are used and changed, to build an attraction.

The function of flocculation should not be explained further in this post. Pretty much every pool has a supplier, who interprets its own philosophy behind the operation.

Graphic 2: Operation of the flocculation, www.pfeiffer.cc

It is only important: The flocculation is needed! A functioning flocculation makes filtration possible at all. Without the flocculation, the particles would be too small, to be deposited. Only the agglomeration to larger flakes prevents, that the particles can pass through the filter unimpeded.

To limit again: This article deals only with depth filtration. All other filtering methods, how far they may be widespread, must be measured against the respective expenses and results.

From theory to practice

Well known is the principal design of the filter as large closed pressure vessel, through which the water is pressed with strong pumps. These filters are optimized to their use for decades and in thousands of applications. The pressure vessel may be made of different materials, as long as these materials can withstand the pressure up.

Already in Post to the selection of pumps we have referred to the pressure conditions in the pipes. To paraphrase a famous quotation I want to present it as:

"What is a pressure filter? Since we simulate ourselves quite stupid, and say: a pressure filter is a large, round, black tube. And the large, round, black tube has two holes and sand inside. That one hole, there the water flows in, and the other hole, we'll find out later ...

Photo 1: filter group 8 piece, Leisure Saaleperle Bernburg, 1998, aqua&pools

Now is later! So should "come out" clean water from the other hole, as desired. On the way through the sand, the water loses its pressure, but then still without pump to transport the pool water to and through the nozzles belonging to the gutters. A vicious circle! Because in the filter is thereby the highest pressure in the entire system.

Sometimes, especially if the pumps are designed incorrectly, unfortunately can break such a pressure filter.

Photo 2: ruptured closed filter, aqua&pools

And all that, because we do not have time and therefore prefer to "closed rapid filters" to DIN 19605 purify the water. At the same time nature makes something completely different. Since millions of years, the water is on

its cleaned by sand layers on the way from the surface into the groundwater . Completely without pumps, valves, tubes. Ok, the area and the regeneration power of the organisms living in, we have not available, but the physical effects of gravity can be used quite. For all potential quibblers: Gravity is, according to Einstein, no force! But please let us the beautiful term "gravity" here and use exceptionally today.

The gravity filters

Nevertheless, we should remain correct. What drives the water through the sand? When closed rapid filters the idea is quite simple, it is the pump. But when gravity filter, it is the weight of the water volume (Gravity) and the air pressure on the open water surface.

The height difference between the water surface and the "free outlet" of the filter naturally determines the pressure and volume flow of the filtrate. Now you can not position each filter in sufficient height to achieve the desired values. But it can support the water drainage by means of a filtrate pump wherein the existing counter-pressure is decreased.

But what is the advantage of such filters? Primarily, the form does not need to be optimized by the much lower pressure to the circle . It can be used as base any rectangles, which in turn improves space utilization.

Photo 3: Gravity filter of WTA Plauen GmbH, 2013, aqua&pools

Especially the local assembly, regardless of the progress of the building, allows a cost-effective variability of resources.

In which direction of the filter evolution we move, is left up to each. Some speak of a rediscovery, others, of course it is a thorn in the side. In my opinion the modern gravity filter is a positive and beneficial development when taking advantage of the properties correctly.

The next filter evolution step: Modular filters!

Yes, it gets even better! Be in the example with the nice fitter in the window, the filter still 90% produced locally, offer other companies, these filters already as a modular structure. The modules are made so, that they can be comfortable as a armchair brought to the site and assembled there. Attention is paid to maximum prefabrication, so that the time can be kept short.

Not only I would think at this point at the many "concreted" or "walled-in" old systems, which can be replaced without damaging the building now. The manufacturers have done it too, they have compiled these filters low even according to the often limited space heights, so that even small pool area or container can be equipped with it.

Photo 4: modular gravity filter from. MST-H2O k.s., www.pfeiffer.cc

Where are the disadvantages, with all the advantages? Well, we come back to the quote: Since we simulate ourselves quite stupid, and say: a gravity filter is a big one, gray box. The water flows in at the top and flows out at the bottom."

But flowing up so much into it, as it flows on bottom below, surely that is not so easy. It takes a control of the water level, therefore must also be measured, how full the filter is just.

The manufacturers solve this differently. It should already have been Technicians, the felt to be able to measure the static pressure during the filtering operation by the filter material.

Conclusion is, without intelligent peripheral is not manually to use such a filter. Let's stay in the module way of thinking, so is a hydraulic module for filtering and rinsing required too. The exemplarily mentioned company www.mst-h2o.com offers its filters with or without such (matching) Modules and thus has obvious success. The partly unrealistic statements on the website about the advantages, I would like to evaluate as advertising behavior of our Austrian neighbors.

The famous see the bigger picture:

Taking a glance at the sewage treatment plant and equipment can be found after a process step "flocculation" in general, the step "sedimentation". The sediments (flakes) will be animated with different techniques, to settle. Usually working with low water speeds. Well, this time and this place, there is probably rare in the treatment of swimming pool water. But removing the "sediment" before a sand filter would reduce its pressure loss and extend its life. The sand filter could speak concentrate on his main task, to catch the particles. Where is the solution? This task can be taken over by cyclone filters. This filter then also creates the possibly metered powder activated carbon from the neck, before they supported the contamination in the sand-filter bed. Not understood the jab? Incidentally removes the activated carbon inadvertently the free chlorine in the water. That chlorine, which acts in the filter bed to the "contamination" of the porous surfaces.

Because the pressures are low in gravity filter, is the cyclone filtering quite possible and effective! Before the big outcry "shearing forces from cyclone destroy flakes" or even "reaction time of the activated carbon can not be maintained" arises, read post to the end. Because later more.

Let us compare times:

We can not compare apples and oranges here, of course,. All filter types need the same features:

- A suitable filter filling for the task,

- long runtime also with flocculant,

- the highest possible number of filter nozzles, which also

- have the known pad pipe under the floor nozzle,

- Ventilation and weir for the discharge of the upper layer of the rinsing water and

- viewing opportunities.

So the planner must calculate before the design of the water treatment plant, what type seems suitable for the entire project. Not to forget the technical measures, in case of power outages or other disturbances the staff, protect the environment and the plant. Now one could open a ranking with valuations similar to the large comparison portals, but I'll try it with a subjective comparison.

Pro pressure filter speaks:

- Large market penetration, therefore "non-monopolized" prices!

- Fast availability!

- Easy to use!

- Large disseminate knowledge about the installation!

- Low operating requirements!

Turning now to the gravity filters. For these filters speaks:

- Several vendors present in almost all price segments!

- Installation according to the "closed" Structure possible!

- Good replacement solution for existing plants!

- Installation possible at normal room height!

- Integrated control of the volume flow!

- Good observation opportunities!

- No transportation restrictions!

A filter is there for filtering!

If only it were that easy. This is because the filter is often given additional tasks in the field of physical or chemical water treatment. But it seems virtually, Place activated carbon on the filter to capture stain , aromatics and bound chlorine. Sense or nonsense of such experiments should enable us to illuminate in a future post. So let's stick with the physical filtration.

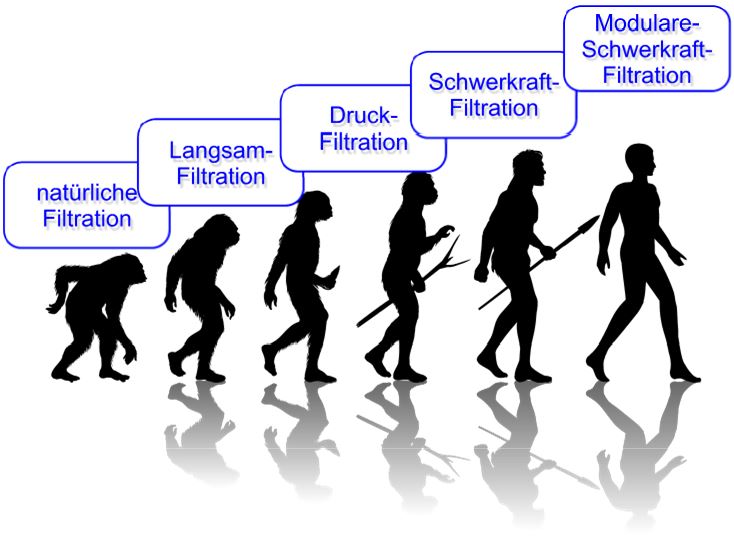

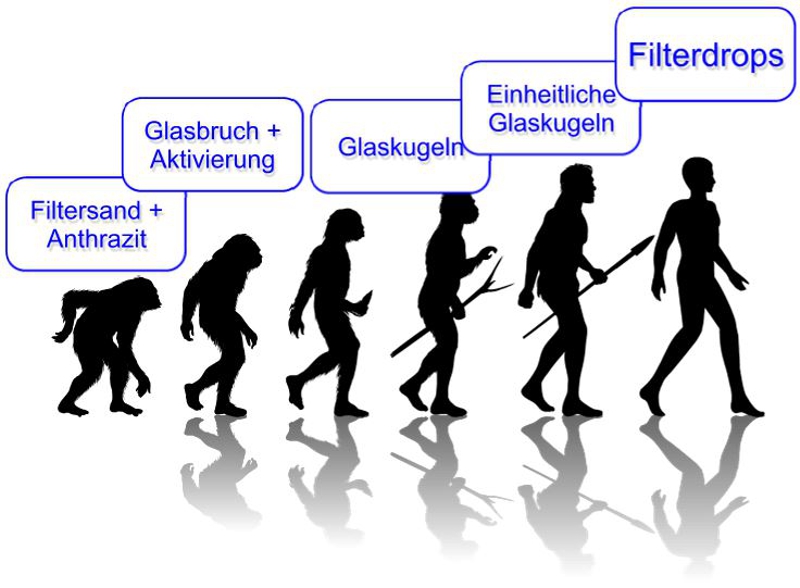

Short interim résumé, my personal evolution of the sand filter:

Graphic 3: Evolution of the depth filtration, fotolia © Neylo, aqua&pools

DIN 19643 are indeed in part 2 some clues to the structure of the filter bed. Here are called grain groups and layer heights. As mentioned in previous issues, there are values called but no prerequisites for your own rating given. It helps, to turn the side glance to our neighbors, Quote ÖNORM M 6216 Edition: 2009-03-15: "If structural conditions so require, the filter layer height may be reduced, if the filtering speed is reduced in the same ratio.

A filter layer height must be at least 0.8m high, the aspect ratio of filter–Layer height in cm to the filter-speed in m/h must be at least 4,0 be."

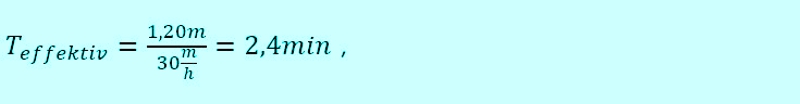

This description actually shows the residence time of the water in the filter layer. We could call it "contact time with the surface of the filter material". Maximum speed according to DIN19643 (or ÖNORM) is 30m/h at 1.20m layer heights, the time is thus obtained:

which left by the particles in the water time, to adhere to a grain of sand. This back door, to vary between the layer height and filtration area, is clearly open in the Austrian Standard. In DIN 19643 it is as it were "painted on the whiteboard". Quotation DIN 19643, 4.4.2.1 Grain Groups, Layer-ups and filtration speeds, Table 1, Footnote a: "If a salinity > 6 % given mass fraction, then filtration speeds and flocculant addition and flocculent type are to be determined experimentally, um in DIN 19643-1:2012-11, Table 2 to achieve required water quality." And at the same place in table 2, Footnote a: "Other combinations (for multi-layer fillings) filter materials and grain groups are to be determined experimentally and to prove." Who would have expected it? Of course, is not described, what should be the "evidence" after the experiment! Perhaps a report by the authors of these sentences?

The measure of filter performance:

Who is to still see through! How is one to "determine" or even "validate"? With which value in DIN 19643-1:2012-11, Table 2 is the filter and the filter material in connection? It could be the turbidity maximum 0,5 FNU or clarity „… View of the entire pelvic floor " be. Simply claim that is probably absolutely counterproductive, because these values can also be achieved without filtering.

Let's try it again with the above KMnO4-consumption. Which may, according to DIN 19643 (described simplified) in the pool water only 3,0 mg/l be above the fill water. But even this is not a fixed aid, because with a "big charge of chlorine" can be, if necessary, the KMnO4-consumption reduce. This happens naturally at the expense of too high a value of combined chlorine. At a differentiated measurement BEFORE and AFTER the filter is already not to think, because as mentioned above, the filter should not and can not achieve this in ONE pass.

Could we fix the performance of the filter to the value of combined chlorine? Or by the values for THM, bromates, chlorites, chlorates, that follow in the list. They are unfortunately only suitable, to assess the overall process, but not specifically the used filters. Luckily there are other engineers too, who take a look beyond the horizon of water treatment in swimming pools. About. 12 Years, took an engineering office in Hanover, whose name means "Innovative water technology" really once also program, a device from the blood analysis and led to the filter a

Particle count

by. The idea is as simple as it is ingenious: Filters trap particles, let the unit counting those particles before and after the filter, then we know qualitatively and quantitatively what the filter catches! Because these instruments can from 1 micron size of the particles,

of course in steps, distinguish. IWT Hannover has in subsequent years on sand filters in operation with freshwater- or salt water concentrates. They have come to an interesting conclusion. Quote IWT, Lecture "Optimization of flocculation filtration": "... The filter material is certainly crucial, but that is not the subject of this investigation. However, it was found, that both the case of filters with a filling of only silica sand (0,71 to 1,25 mm) or only of anthracite (Type I = 1.0 to 1,4 mm or type II = 1.4 to 2,5 mm) as well as multi-layer filters with quartz sand (0,71 to 1,25 mm) and anthracite are no differences. …“

Let's just take an example, here is a modular filter the MST H2O K. S., in which I was able to verify the effectiveness of the filter with a special glass ball filled. The explanation for the glass sphere filling is only touched upon here: Best filter- and rinsing results and the lowest possible pressure difference in the tested module with filtering materials. We will discuss in more detail below on different materials. The Particle counter was constructed 4-channel for this purpose.

- Measurement 1: before flocculation,

- Measurement 2: after flocculation close in front of the cyclone filter,

- Measurement 3: after the cyclone filter to the filter bed,

- Measurement 4: behind the gravity filter,

The measurement before the flocculation (1) is not interesting for this article basically. It allows the representation, whether the flocculant served its purpose and as its name demands it: forms flakes. Of course, the flocculation previously been optimized. As? Presenting this would go beyond the scope of this article and could become a later topic.

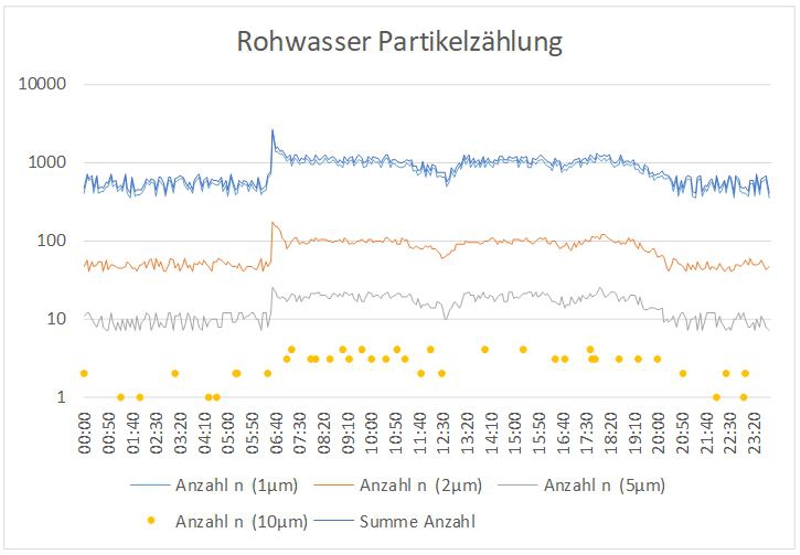

The raw data of a measurement at a measuring point look like:

Graphic 4: Particle count raw water, aqua&pools

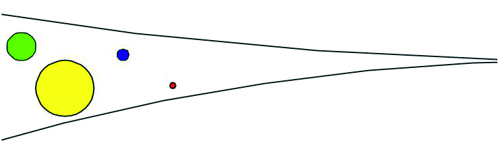

Without a little practice, we can not imagine including much. Therefore, here is a graph to illustrate the size of the flakes:

The upper curve (black lines) is a sand grain with diameter 1.25 mm, which is touched by the lower sand grain diameter of 0,71mm. In the gap particles fly straight with 1 micron (red), 2µm (blue), 5µm (green) and 10 microns (yellow) past.

Graphic 5: Size comparison sand and particles, aqua&pools

Nice to see is also, that there's no more "clamps".

A closer look at the first chart you can see, that is spoken of "number of particles". The logarithmic scale is deceptive something, because the 1-micron particles are clearly in the majority. The particles can be about. 1000 fighters send into the race, wherein the 10-micron particles rarely pass. But I wanted to spare myself the work, 1000 to paint red dots in the gap.

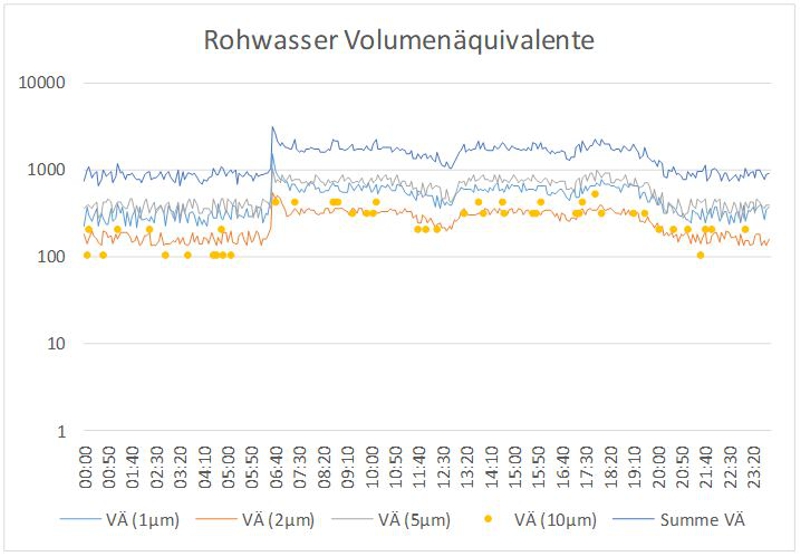

If we add up the sheer number of different diameters, Although we get a sum, but that does not provide meaningful. Better to understood, it is, if we look at the flakes as balls, equip with a volume unit and then sum up. The theory we must not exaggerate, as flakes just are not balls and be compressed depends on the size. so that the rarer large flakes get an adjusted value. The values from the upper diagram now looks so:

Graphic 6: Particle count with raw water volume equivalents of, aqua&pools

With the conversion we can see better, what flocculation, the cyclone filter and gravity filter do. But beware, these are still values "μm³ per milliliter". Who fun with it

has, can now calculate its filter absolute values. But be careful, the margin of error will be so huge.

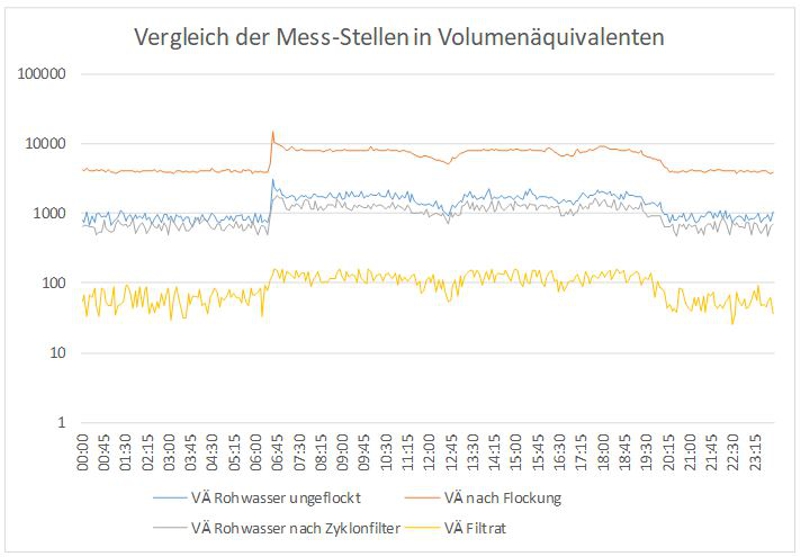

In the top diagram, we have worked with the individual particle sizes. In the next chart these volumes are summarized, so that the representation of the measurements can be made all measuring points.

The blue line in the next graph indicates, which particle volumes exist without the influence of flocculation. This is followed by measurement after flocculation, shown with the upper red line. A large distance between blue and red line shows a good effect of flocculation.

Graphic 7: Particle count with raw water volume equivalents of 4 Point Numbers, aqua&pools

The red line is as though our starting point. It shows the volume units after successful flocculation. In our example the measuring point comes after the cyclone filter. In the cyclone filter gravity is complemented by the centrifugal acceleration and thus particularly the earth-rich larger flakes are deposited. It remains the pitiful remnant, visible reference to the gray line.

Could be the flakes simply destroyed by the cyclone filter or hindered in their education? Of course! But then no mud residue in the filter would be observed. When using a cyclone filter it all depends on the correct choice and the right rotation speed.

Photo 5: 3-multiple battery cyclone filter, Reinstalling, aqua&pools

Now the sand filter acts on the rest and removes the flakes to a very large and important part. In this case, a modular gravity filters from MST H2O.ks with a filter filling of glass beads. In this special filter filling we will discuss in more detail later.

The yellow line in (repeated) chart shows, that only about. 100 Volume equivalents could pass the filter bed. Paying attention to the logarithmic scale of the chart is significantly, that from 10000 Volume equivalents of the particles to 100 was reduced, So these are 99%!

This is not the place, to all options, which can be carried out with the particle count on the settings of the filter and the filter material, to describe. But I think it is a good tool to question the effectiveness of the filter and to prove it in case of doubt. According to my information IWT Hannover could help even some pool operators looking for causes and optimal settings.

Now we know, how to assess the filter in its design. In the previous section we discussed only in passing on the used filter material. But with the particle count to get even the relationships between effectiveness and filter material on the track. Let's begin with thoughts on

Evolution of the filter material

The DIN 19643 refers to filter sand according to DIN EN 12904. In general, it is a natural product, that is mined from an open pit gravel or in the sea.

The effect of the filter material is in addition to the above-described already (simplified considered) mechanical retention of solid substances, but also in the following operations:

- Accretion or coagulation,

- Precipitation of colloidal particles or flocculation processes,

- Oxidation processes,

- catalytic processes,

- interfaces- and flow processes,

- Adsorption processes and

- Microbiological processes

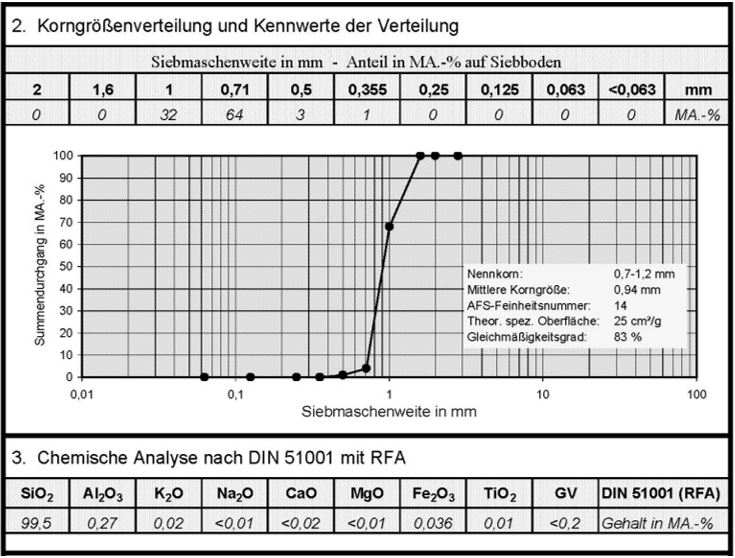

If we limit ourselves first to the desired physical effect, then usually filter sand and gravel filter used for filtration. The properties can be found usually in the manufacturer's data sheet. Here is indicated, what particle sizes the sand consists of. Der Mix, which in the defined area according to DIN 19643 should be, is precisely defined. Here is a typical product specification for filter sand:

Graphic 8: Composition of filter sand, Extract from manufacturer's instructions

For understanding is particularly important, that, presumably for production-technical reasons, also so called undersize, so the grains are smaller than the product information, up to a proportion of 5% are allowed. Five percent are not much, but the percentages are reason enough for some manufacturers to give a hint. For example Quote SBF "Basis of filtration", Page 2:

„Important: After the pour in and washing of sand filters perform a filter flushing and then the fine proportion of sand (according to DIN max. 5%) mechanically removed by peeling. This will prevent, that the filter service life is not reduced by fine sand. "

As so often, we wonder why! Well, the fine fraction, the undersize, reduces the pore size so strong, that the service life of the filter is reduced. At the same time it's really hard, This undersize "get rid of" by means of a filter flushing. Manual labor is in demand, but you will need into the filter.

Normal filter sand

... sorts itself as if by magic. After rinsing, the large heavy grains are down and the small light grains above.

Unfortunately, the top layer is also the layer, which receives the most dirt. The pores of this layer are clogged first, the necessary pressure increases and the lower layers may still be clean, are not reached by pollution.

Photo 6: Used and hardened filter sand, aqua&pools

Sometimes the filter sand looks so similar after a few cycles of the photo 6 ... Here was a kind of concrete in the filter, which can only be loosened with strong tools. If you look closely discovered in photo features for "granular". This may not be in Germany. For here the DIN says: "... natural sand, not broken …".

There are so regularly countermeasures against the top tight-porous layer in demand. You have to incorporate a material, which although has a larger grain, but still slowly sinks in water. Common arr anthracite H or N. Some people believe, at the same time a wide variety of water features such as smell and taste, Discoloration and similar to affect, but that's neither the main goal nor is it as easy as I thought.

In a later post we will deal with the physical conditions for the filter flushing. Here we will only mention, that the sink rate of the big easy (Anthracite-) Grains must be still larger than the water speed. Unless: Bye dear filter material!

Before the pump selection, see last post, so is therefore a calculation of the sink rate of the filter materials necessary. What do we need?

- CW value, we can ignore for such small objects.

- Density of the filter material, which goes straight into the calculation.

- Diameter of the grain, goes one square in the calculation.

- Temperature of the rinse water, that goes beyond the Reynolds number in the calculation and thus has significant proportion of the speed.

Hot water = higher rinse water consumption!

All theory is gray: The calculation does not relieve us of the obligation, adjust the flushing speed correctly in practice. Otherwise, you know that: Bye filter material!

The second step of evolution: Broken glass

Sand consists mainly of SiO2, but also a number of other substances. He stands in a chemical interaction of water, takes substances, emits substances. A look back at the graphic "composition of a filter sand" is enough to see, what is even more so in the sand. Not always this interaction is purposeful. Glass, as finishing of the sand, is inert and minimizes these chemical processes. It seems a good idea, to use glass as a filter material.

Photo 7: Broken glass as a filter material, fotolia, ©in-foto-backround

Untreated glass breakage has sharp edges and could the filter, and with breakthroughs, the bathers too, hurt.

Especially critical, we should see the irregular shape of the grains. In filter operation results in an irregular layering with large proportions of touching and ineffective surfaces. In the filter flushing in turn is the contact of the surfaces and thus a comprehensive cleaning effect, almost impossible.

The third step of evolution: Activated surface

According to one manufacturer, the glass material is "activated" thermally, thus creating a porous surface. This surface will accumulate dirt better and at the same time prevent the growth of microorganisms. I have not been able to test both information so far, the informations are mentioned for completeness.

Following this manufacturer informations, then the surface of the glass breakage can therefore be changed so, that the particles accumulate better.

Philosophy of surface.

Another branch of this evolution is regarding the design of the surface in the opposite direction. Was the glass breakage, the irregularity of the fragment also transferred to the surface, so it is in the other branch to the optimization of the volume in relation to the surface.

Sometime in school, I think at the high school, everyone has to deal with optimization problems. It is always valid, to find a maximum or a minimum. Our ancestors did not need school to know, that maximum volume meets minimum surface at balls. According to the invention of the sand-blasting, it has finally taken a while until the glass ball blasting. Likewise, between sand- and glass ball-filtration.

I am of the opinion, it depends on, water flow, and thus the particles, to lead possible slowly and smoothly along the surface of the filter material. Every bump triggers a flurry of, this flow of interrupts and the speeds and directions of the particles increases. That's why I prefer the following solution:

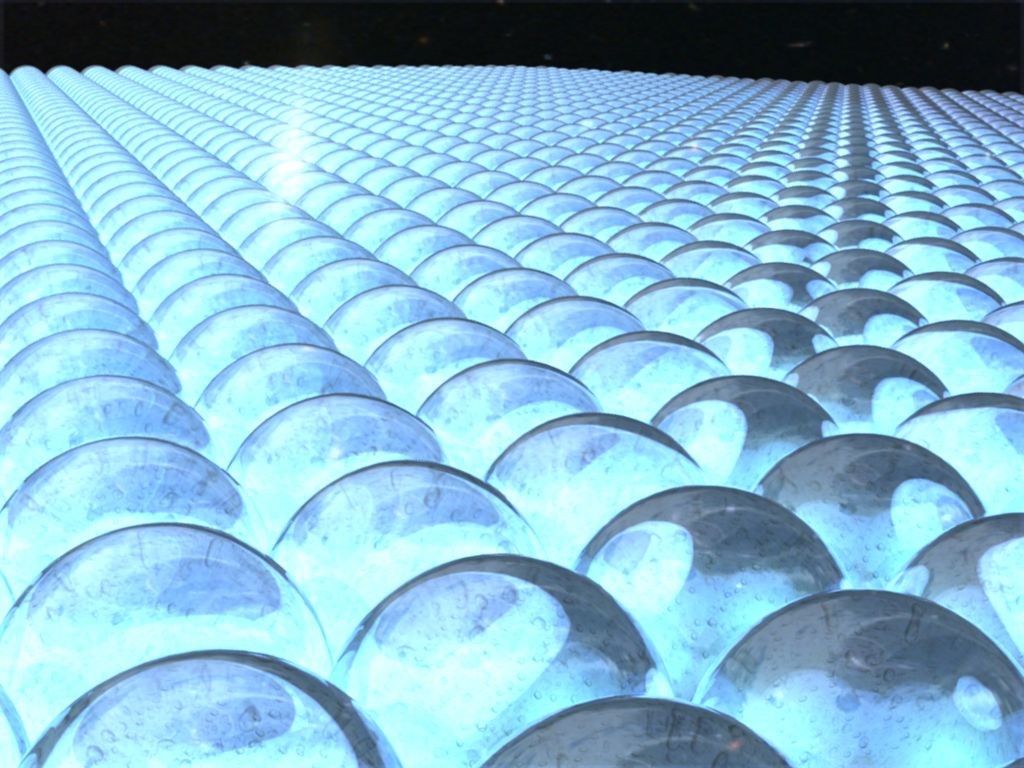

Step of evolution 3a: glass beads

Even if the price is far from the sand, the beads are spreading more and more. Our friends in Austria can not get used so well, that sand and glass are related to each other, but here and in the north there are more pools, that rely on the small beads.

What is the advantage? Well, if two balls go in touch, then the probability of contact is the same for each point.

So it's only a matter of time, until all points have touched during flushing and cleaning. If it do two irregular body, then it comes to a large extent a matter, which points go in touch.

Is it a pit, then the other body must impinge with a peak. With this background, that bacteria like to sit in pits ... the rest, everyone can imagine themselves.

The fourth step of evolution: Uniform glass beads

Transferring the DIN 19643 to the glass beads, then there is the diameter of the range from 0,71 … 1,25 mm use. Then, beads of different diameter are confused. This natural chaos creates no defined pore size.

The resourceful pool professionals among us know this guarantees a solution: Put the glass beads time! At the end of each filter flushing is not the abrupt stop of the flow. Instead, the speed is slowly reduced and the glass beads so beautifully arranged, so that they achieve a high packing density.

It could be easier, if the glass beads are not distributed across the size range, but having a uniform diameter. The result is a natural smooth and dense packing, which brings the filter performance at its optimum. All pores are the same size, all paths are of equal length. In areas, that are more loaded with dirt, the flow resistance increases, resulting in a stronger flow of clean areas. So we get a natural balance, which our filter takes best possible advantages.

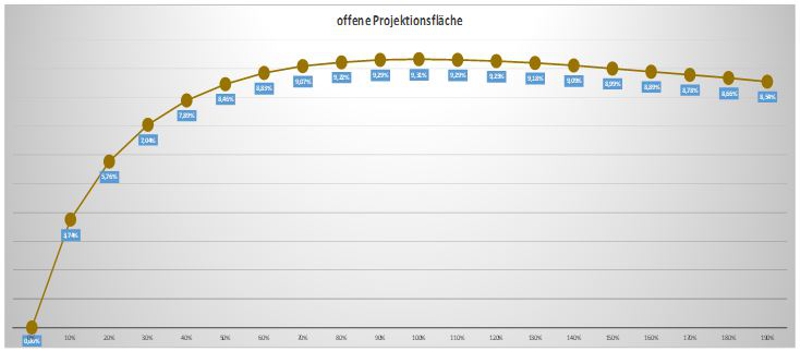

Besides, also the open-pore surface changes, but this is probably only marginal. Here still the little excursion into the theory:

Diagram 1: Influence of the mixture of grain sizes

Consider the grains of sand in two dimensions, then results in the same sand grains, so when 100% a part of the pores 9,31%. This is the theoretical maximum. If a grain at the lower end of the allowable range (0,71 mm) and two at the upper end of the permissible range (1,25 mm) is dimensioned, then from the sand grains have a ratio of 56%. This results in a porosity of 8,73%

Here are the first thoughts after the price will rise. Sand is cheap, Glass beads are expensive. As so often in life, but it comes at the period under consideration. When the filter flushing is set too high, it's a really short period of time. Then everything is gone for the first flushing! This is rarely the case, so we look at the filter flushing. Considering only the rhythm, caused by pollution, then you can double this period with glass beads. The additional costs for the glass balls are thus according to experience about. 1 year established.

Have we arrived at the top of my little filter material evolution? Certainly not!

Rather, it may only issue now, to unite all the advantages of different materials.

These benefits are, in a disorderly order:

- Pore size from the definition of filter sand,

- Density equal to or only slightly smaller than sand, so that the flushing systems must not be changed,

- Density- and grain size difference of anthracite,

- chemically inert properties of the glass,

- anti-microbial surface of the activated glass breakage,

- trouble-free flow on the spherical surface and

- uniform pore through ball diameter in a narrow tolerance range.

This combination of properties in a material, there is not yet? Then we change that now!

The fifth step of evolution: Filterdrops

What no one else did, I have to do it myself then! So I have embedded the benefits in a single material, because the properties:

spherical shape, Diameter within narrow tolerances, inert and anti-microbial surface and variable sink rate of the material seem important to me. Therefore I beg, to represent this my personal evolution of the filter material similar to the filters themselves.

Graphic 9: Evolution of the filter material, aqua&pools

Nevertheless, everyone can and should make his own image, what characteristics are important to him at the filter material.

The following types of filters Drops will be available:

- supporting layer drops: From the upper part of the size range for supporting layers in accordance with DIN 19643.

- filter layer drops: From the size range of the filter layer in accordance with DIN 19643, but by approximately ±0.05mm sorted..

- Topcoat A-Drops: From the size range of the anthracite layer according to DIN 19643, but by approximately ±0.05mm sorted.. Sink-speed is less than the filter layer drops.

- Topcoat B-Drops: Twice the size of A-Drops, but by approximately ±0.05mm sorted.. Sink-speed is less than A-Drops.

Of course, the future shape of this description is striking. The reason for this. The application of the material at the German Patent- and Trademark Office takes as his time as the search for a low-cost manufacturing base. Because it makes no sense, the deep bed filter (pricing) wanting to fill with diamonds. In the end it is supposed to be financially attractive.

Graphic 10: Filterdrops, aqua&pools

Each individual avoided contamination of the water or any avoided liter flushing water justify the thought "outside the box" of the swimming pool.

Especially important is, that filters Drops can replace the normal sand in conventional technology. Do not expect miracles, but there are now enough examples of biologically contaminated multilayer filters, whose filter material therefore had to be replaced.

More information I will in www.filterdrops.de assemble. One can expect, that with the delivery of this new filter material beginning 2020+ can begin.

Yes, cleaning is also fallen short in my opinion here. Therefore it's done in the next post with cleaning the deep bed filter further. Thank you for the interest! I am glad about every feedback.

Print View

If the view is not yet visible, Please wait a few seconds or refresh the page.

Thank you!

Loading...

Loading...

For registered members here the print version as PDF:

[wpdm_package id=’3285′]

2 Responses

killlaurb

What is this called i am from SPAIN.

I registered a lot time ago. Can i see this web without adblocer?

thanks )

aquaandpools.de

No you can’t. Please specify your question or wishes.