Published in: Das Schwimmbad und sein Personal, edition 05/2020

... the other comparison of the pressure precoat filters.

|

Preamble The first article related to precoat filters in the edition 10/2019 was provocative and sparked some discussions. My friend Dipl.-Ing. Achim Rietz from Zeuthen near Berlin sought the interview. As an expert, he has already planned to use several pressure precoat filters, accompanies and as it is his job- also rated afterwards. He sees filters from a different perspective, through another (Floating) glasses. I do not want to withhold this view from you. That is why he presents his experiences for us in a sober comparison. Have lots of fun with it ! |

Positioning the "pressure- Alluvial filter technology "

Initial situation In practice there are always ambiguities or fears of contact with the technique of precoat filtration. There is no reason for that, because the technology is manageable. This technology has been in the field of swimming pool water treatment for over 50 Years in Germany and since then in DIN 19643 listed as one of the treatment processes.

Hoelscher Schwimmbadtechnik GmbH was a major pioneer in this area & Co. KG from Mühltal, who has now passed on her experience to the generation after next. Since about 10 Years, the Defender® brand from the American company Neptune-Benson has also been on the German market. In the Berlin area in particular, more than 15 Plants for pool water treatment equipped with this technology. Nevertheless, this technology is hardly used in Germany. From the author's perspective, this is partly due to the fact, that most of the major plant engineering companies own their own- and have developed multilayer filters and have brought them to the market in the past.

The technology of the precoat filter can make a valuable contribution, particularly in times of discussion about environmental pollution and resource conservation. Here play alongside the water- and wastewater savings, the energy saved for heating the pool water and the space saved for enclosed space also play an important role.

In the following sections, the need for an active filter area and the corresponding dimensions of the space required for the filter container for the pressure single-layer filter and pressure precoat filter to be operated with pre-pressure are compared. This is done once without and once with an adsorption stage, So under the action of activated carbon, compared.

The term pressure multi-layer filter stands for the use of a layer of activated carbon in the layer structure.

Basis of comparison

Below are just the pressure filters for the one- and multi-layer filtration as well as for precoat filtration.

Pressure precoat filtration is currently a purely mechanical filtration stage - it can work with the active- and operation of a pressure single-layer filtration.

The pressure precoat filtration has – just like membrane ultrafiltration – no stage for adsorbing the bound chlorine.

If measures to minimize disinfection by-products are required, the single-layer filter can be supplemented with an additional activated carbon layer. With the precoat filter, this is only possible through an additional adsorption stage. This is often done by using an activated carbon filter in the bypass of the filtrate line. The order of magnitude has proven to be a reasonable order of magnitude for such an adsorptive stage in the bypass 20% of the circulation volume flow.

The pressure single-layer filters are therefore compared below with the pressure precoat filters. In the second step, the pressure multilayer filters are then compared with the pressure precoat filters with an activated carbon filter in the bypass.

For the following comparisons, the volume flows in steps of 20 m3 / h assumed.

For the pressure vessels of the pressure single-layer filter and the pressure multi-layer filter, the diameters were in steps of 200 mm set. So there were filter containers of the diameter 1.000 mm, 1.200 mm, 1.400 mm and larger assumed.

Comparison of the required filter areas

Many old systems are getting on in years. Are these now being renovated, The existing protection may be lost and the applicable standards and guidelines must be applied during the renovation. Many of these old systems are still running with pressure on- or pressure multi-layer filter with a filter speed of 50 m/h.

For these filters the DIN 19643 a filter speed of 30 m / h recommended. For the sake of simplicity, only the filter speed of 30 m / h when using pressure single-layer filters and pressure multi-layer filters.

The filtration speed of the precoat filter should be according to DIN 19643 In the range of 5 to 8 m / h. Have the author's experience, depending on the make, an optimal ratio of speed

and pressure loss at 4.0 m / h of the filter material.

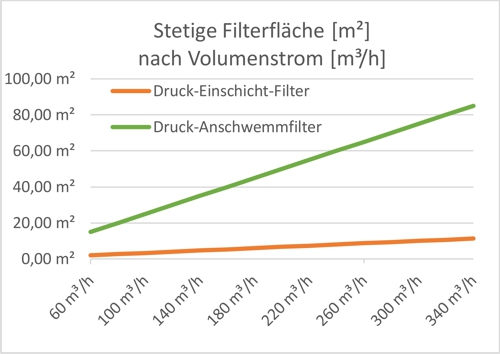

The diagram shows a comparison of the required filter areas in relation to the respective circulation rates 1 shown. The difference between the two curves is due to the different filtration speeds.

Diagram 1: required filter areas at 30m / h and 4m / h

For both types, Pressure precoat filters and pressure single-layer filters, there are manufacturer-related gradations between the dimensions.

The pressure single-layer filter is the inner cross section of the filter container. Restrictions due to internal installations, like the cross section of the raw water pipe, are not taken into account in practice and here.

In the case of the pressure precoat filter, the filter surface is on the surface of the filter aid material, So the filter elements with the washed-up material.

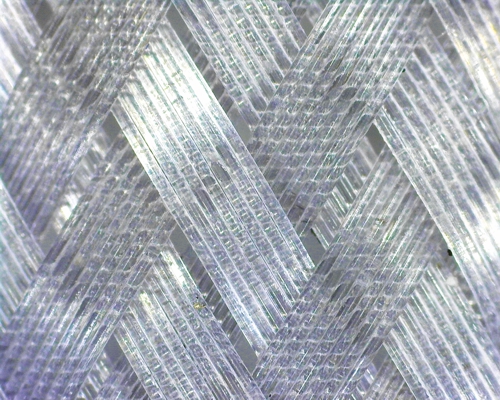

Photo 1: Tissue under the microscope, Source aqua&pools

During the precoating process, the filter aid material builds up on the tissue step by step. The visible pores in the tissue are covered by a layer of filter aid material. It is therefore important, that the entire surface of the tissue is reached by the flow and the particles.

Vacuum precoat filters not considered here suck the water through the fabric.

In the case of pressure precoat filters, the fabric generally requires a cylindrical substructure, on which the tissue is stretched.

Many of these filter elements are arranged in the container at a relatively close distance. The arrangement and the distances depend on the manufacturer.

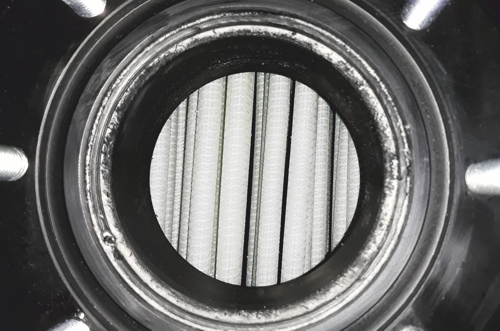

Photo 2: Filter elements through a flange, Source: aqua&pools

This means that considerably more filter area can be arranged in the cross-section of the container. The comparison of the footprint changes dramatically, With the pressure precoat filter, more than 50m² filter area can be accommodated on 1m² filter stand area.

Comparison of the space requirements of the filter systems

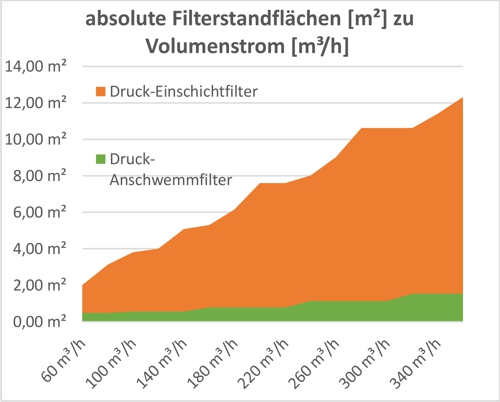

The diagram shows a comparison of the absolute space requirements of filter systems, the pressure single-layer filter and the pressure precoat filter 2 shown. In the case of the pressure precoat filters, the diameter of the "Defender" brand was used for the respective volume flow.

Diagram 2: Required stand space Pressure single-layer filter and pressure precoat filter

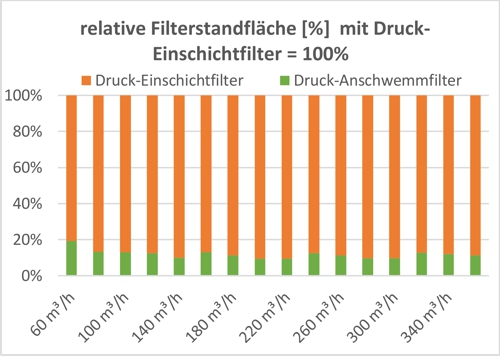

If you now set the percentage ratio of the space requirement of a pressure precoat filter with the space requirement

of a pressure single-layer filter, the diagram is shown 3.

It can be determined, that the space required for the pressure single-layer filter is around 80% and the space requirement of the precoat filter at only about 20% located.

Diagram 3: Ratio of space savings

Single-layer pressure filter – Pressure precoat filter

Of course, this space saving also applies to the piping area, of the fittings and the circulation pumps. Enormous space savings and thus savings in enclosed space can be achieved here.

Graphic 1: Ratio of diameters 1 to 2,9 for 200m³ / h, Source: aqua&pools

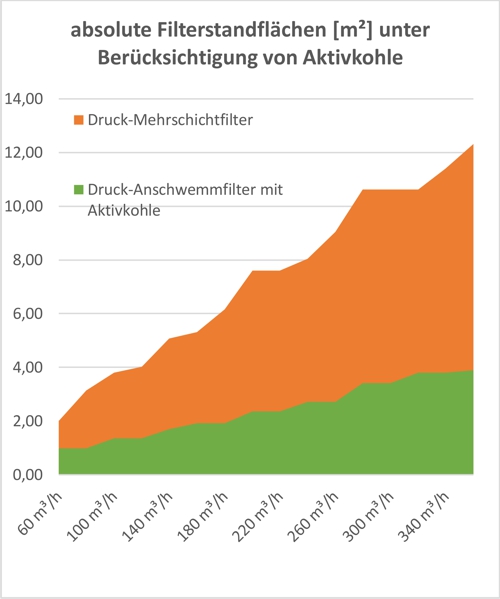

A comparison of the space requirements of filter systems, the pressure multilayer filter and the pressure precoat filter with activated carbon filter is in Diagram 4 4 shown. For the pressure precoat filters, the diameters of the "Defender®" brand were used as before for the respective volume flow. In the additional stage with an activated carbon filter in the bypass of the filtrate water line, a partial volume flow of 20% scheduled.

Diagram 4: Required floor space for printing multilayer- Filters and pressure precoat filters with activated carbon filters

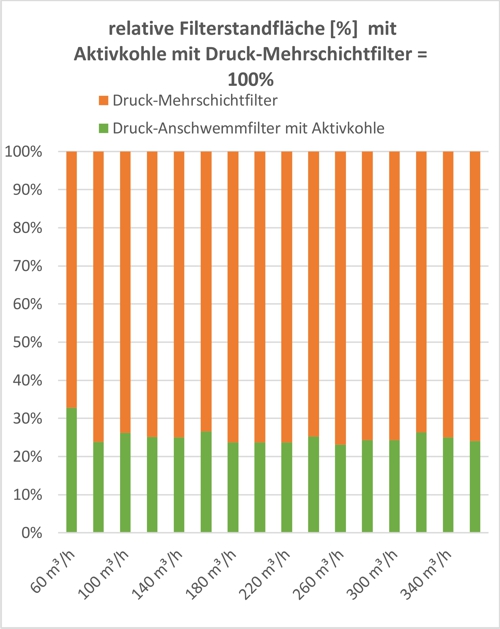

Diagram 5: Relationship of the space requirement for the print multilayer- Filters - Pressure precoat filter with activated carbon filter

This can be determined, that the space required for the pressure multilayer filter at about 75% and the space requirement of the pressure precoat filter with activated carbon filter is only about 25 % located.

Comparison of the flushing water quantities

The filter rinsing on the pressure precoat filter consists of this, that the filter content including filter aid material and accumulated dirt is drained off. Only the content of the pressure precoat filter is the waste water volume. The conditions for the disposal of the wastewater loaded with the filter aids from the filter rinse must of course be clarified in advance with the disposal company. A simple solution for this is to install a rinsing waste water container, which is used as a decay basin. The wastewater is then fed to the sewage system with a time delay, so that solids can settle and separate, as required, can be suctioned off and disposed of. After this rinsing, the new filter aid is sucked into the filter container by the Defender® brand using a vacuum system. Then the automatic is started and the procedure for the addition of the filter aid starts again automatically. The raw water mixed with the filter aid is only circulated through the filter for a few minutes. This happens as long as, until the functional filter cake has formed on the carrier material for the filter aid and finally only clear water circulates. Only then is the path to the pool cleared and the entire cycle restarted.

Automatic suction is already available for larger systems with several circuits- and filling station.

Now you could argue with it, that with this filter flush over 90 % the flushing water quantity of a pressure single-layer filter is saved.

The fact in itself is correct - in relation to the filter rinsing. However, the required dilution effect against dissolved substances is completely neglected.

When comparing with a pressure multilayer filter with activated carbon layer, of course only a pressure precoat filter with an additional adsorption stage can be used, here an activated carbon filter in the bypass, to be viewed as. Because the activated carbon filter can be rinsed separately, can be controlled with the number of filter rinses of this activated carbon filter, the orders of magnitude for the necessary supply of fill water and thus the dilution effect.

From the author's experience to date, pressure precoat filtration with activated carbon filtration in the bypass of the filtrate line can save more than water 50 % compared to the flushing of pressure multilayer filters with activated carbon layer.

Graphic 2: Pressure precoat filter for 200m³ / h,

Diameter 1000mm, Source: aqua&pools

These numbers have been confirmed in practice. In some cases, the water savings are considerably higher - this is not the case with a theoretical comparison.

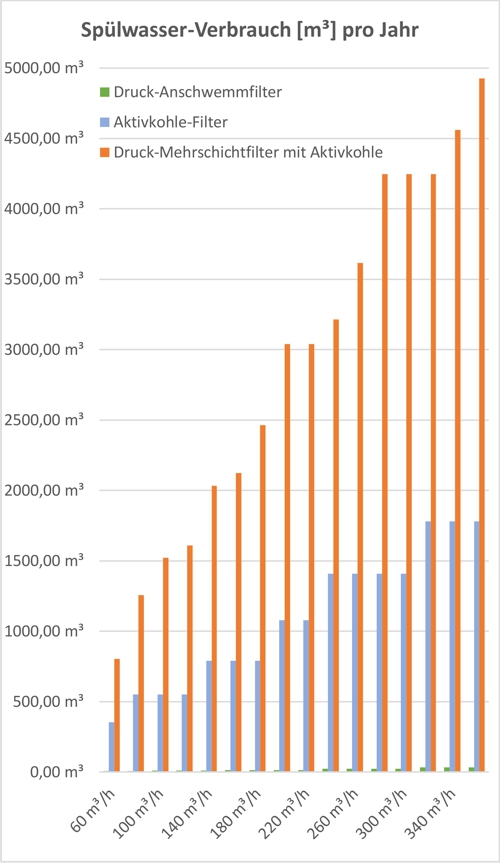

Below are the flushing water quantities of pressure precoat filters, Activated carbon filters in the bypass and pressure multilayer filters compared.

The DIN 19643 recommends filter rinsing twice a week for single-layer and multi-layer filters. When rinsing is subsequently from 2 Rinses per week 50 Operating weeks out in the year.

Furthermore, for the amount of rinse water 4 m3 per m2 filter area expired. With an operating time of the bath of 350 Days a year, according to the manufacturer's recommendation, the "Defender®" pressure precoat filter becomes all 25 Rinsed days. The associated activated carbon filter is rinsed every other day.

Who is looking for the flushing water quantities for the pressure precoat filters, must pay attention to the small green dots after the zero line. The diagram is stretched just for that.

The following relationships thus result:

Diagram 6: Rinse water quantities Pressure precoat filter with activated carbon filter, Multi-layer pressure filter

Conclusion

The pressure precoat filters only need approx. 20 % the footprint compared to a pressure single-layer filter.

The pressure precoat filter in objects offers particularly great advantages, who have previously achieved good water values without activated carbon.

This is particularly important when renovating outdoor swimming pools. This in particular from the aspect, that during a refurbishment, the existing protection is no longer applicable and the filter speed of 50 m / h since 1997 by the filter speed of 30 m / h is to be replaced. This means that a larger footprint is required when replacing the pressure single-layer filter as part of a refurbishment.

The advantages of the precoat filter also apply to objects with an existing activated carbon level. The space saved here is also far greater with an activated carbon filter in the bypass 50 % compared to multi-layer filtration.

If flushing water is required, there is considerable savings potential through the use of pressure precoat filters. The size of the saving naturally depends on the quality of the fill water, the usage behavior of bathers and many other factors more. However, the principle of pool water treatment should always apply:

"Hänschen can be 100 Wash your hands - at some point the water has to be changed. ”This means the desired and necessary dilution effect by adding fill water. According to DIN 19643 should this at 30 Liters per day per swimmer. Experience shows, that, especially in outdoor pools, considerable amounts of rinse water with the same

and standard-compliant pool water quality can be saved.

Comparable and reliable information about space requirements, Size of the enclosed space, The need for rinsing water and the associated saving of energy for water heating can be determined by any qualified specialist planner based on his experience and the data of the specific application.

In view of the enormous savings potential, it is worthwhile, to commission a qualified and experienced specialist planner with such a comparison.

Dipl.-Ing. Achim Rietz,

Achim.Rietz@gutachten-schwimmbad.de

Tel: +49 33762 49135 · Mobil: +49 151 128 698 32

A postscript:In my opinion, Achim Rietz presented very well here, that the comparison is worthwhile. It mainly relates to spatial advantages for the pressure precoat filter. One can find out about the lower weight, wet sand is heavier than water, on a floor ceiling or by installing through a hole in the wall, called door, to chat. However, this can immediately give advantages in operation- and even transportation weight can be represented, that play a big role in the environment. The biggest advantage for me is the separate use of activated carbon. In more and more systems, a support on the multi-layer filter is becoming a cause of contamination, which can hardly be mastered in the pressure multilayer filter. Achim, Thank you for this contribution! aqua&pools |

Loading...

Loading...

Leave a Reply

You must be logged in to post a comment.